Official Disitributors to UK & Ireland for ThermoBreak Insulation Products - Over 20 Years in the Insulation supplies and service industry

Thermobreak™ Thermal Insulation

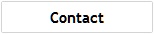

Thermobreak™ is a leading flexible thermal insulation

material made from physically crosslinked,

closed-cell, polyolefin foam, thermally fused to pure

reinforced aluminum foil. Thermobreak™ is also

available with adhesive backing. Thermobreak™ Tube

insulation is a preformed tube thermal insulation for

steel, copper and plastic pipes.

Thermobreak™ thermal insulation provides superior energy saving performance. It has a lower thermal conductivity than other flexible closed cell thermal insulation materials and has near zero vapour permeability. Its all-in-one concept enables fast and simple installation, and trouble free operation, in a variety of environments.

Thermobreak™Thermal Insulation and Thermobreak™ Tube are manufactured in Australia and Thailand.

Thermobreak™ thermal insulation provides superior energy saving performance. It has a lower thermal conductivity than other flexible closed cell thermal insulation materials and has near zero vapour permeability. Its all-in-one concept enables fast and simple installation, and trouble free operation, in a variety of environments.

Thermobreak™Thermal Insulation and Thermobreak™ Tube are manufactured in Australia and Thailand.

Advantages of Thermobreak™

• Optimum Thermal Insulation - Thermobreak™ can

solve tight clearance issues with its very low thermal

conductivity (k = 0.032 W/mK @ 23 Deg C).

• Water Vapour Resistance – Thermobreak™s negligible water vapour permeance (8.19 X10-15 Kg/Pa.s.m) means no additional vapour barriers or coatings are required.

• Safe To Use - Thermobreak™ is completely user friendly and does not emit fibres or dust during installation or in service. Thermobreak™ is non irritant, odourless, and will not support bacterial growth.

• Easy To Drill & Cut - Thermobreak™ contributes to reducing installation time of mechanical services that may be installed afterwards.

• Appearance & Durability - Thermobreak™ provides an appearance and performance that remains unchanged for the life of the building without sagging or giving a quilted look.

• Extensive Technical Support – including ThermaCalc™ computer selection program with full analysis of heat flows, technical information bulletins, independent laboratory testing and Certification.

• Fire and Smoke Standards - Extensively tested to various international fire and smoke standards, such as British (BS) , ASTM, Australian (AS), ISO, and UL Standards. Numerous National body approvals (PSB, HKFS, BOMBA, Qatar Civil Defense, Bahrain Civil Defense, Dubai Municipality).

• Green Building Compliant - Certified Green Star product (VOC), Zero Global Warming Potential (GWP), Made without Ozone destroying agents such as CFCs or HCFCs

• Backed by the financial and technical strength of a global company with locally based engineers.

• Water Vapour Resistance – Thermobreak™s negligible water vapour permeance (8.19 X10-15 Kg/Pa.s.m) means no additional vapour barriers or coatings are required.

• Safe To Use - Thermobreak™ is completely user friendly and does not emit fibres or dust during installation or in service. Thermobreak™ is non irritant, odourless, and will not support bacterial growth.

• Easy To Drill & Cut - Thermobreak™ contributes to reducing installation time of mechanical services that may be installed afterwards.

• Appearance & Durability - Thermobreak™ provides an appearance and performance that remains unchanged for the life of the building without sagging or giving a quilted look.

• Extensive Technical Support – including ThermaCalc™ computer selection program with full analysis of heat flows, technical information bulletins, independent laboratory testing and Certification.

• Fire and Smoke Standards - Extensively tested to various international fire and smoke standards, such as British (BS) , ASTM, Australian (AS), ISO, and UL Standards. Numerous National body approvals (PSB, HKFS, BOMBA, Qatar Civil Defense, Bahrain Civil Defense, Dubai Municipality).

• Green Building Compliant - Certified Green Star product (VOC), Zero Global Warming Potential (GWP), Made without Ozone destroying agents such as CFCs or HCFCs

• Backed by the financial and technical strength of a global company with locally based engineers.

Application Areas

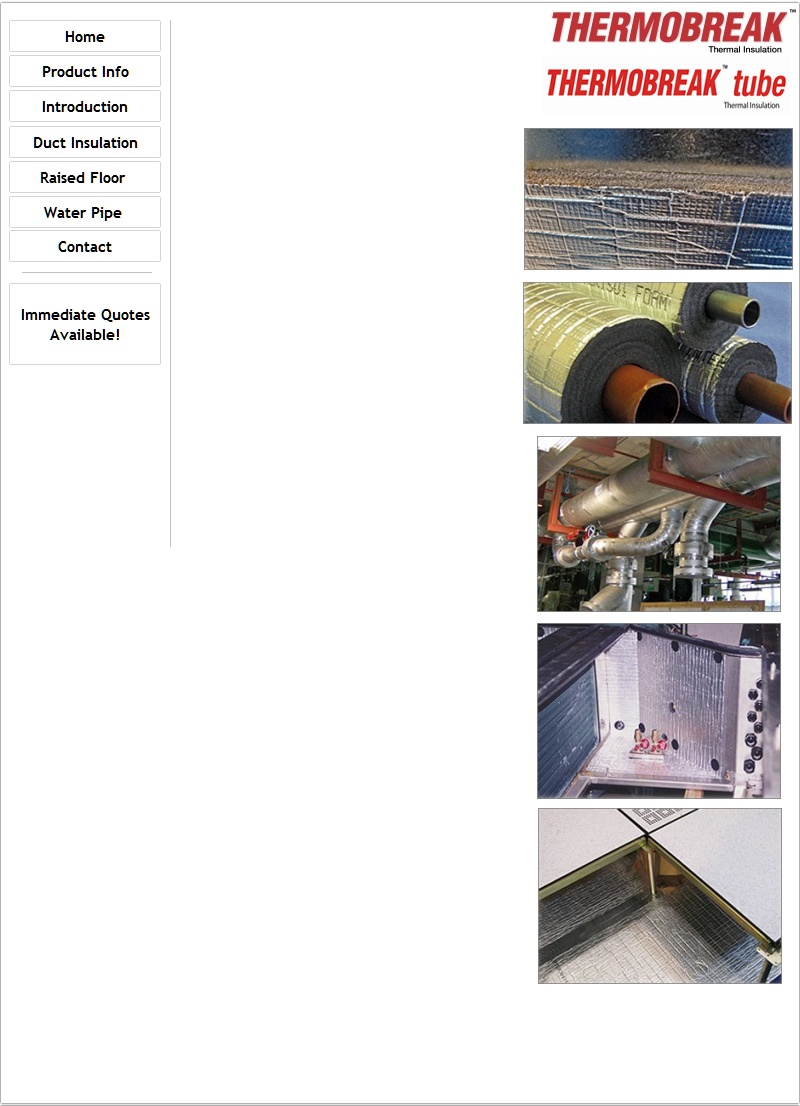

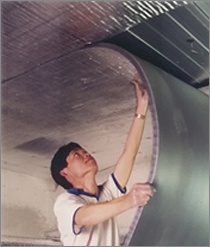

• Duct Insulation

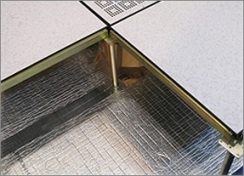

• Raised Floor Insulation

• Underslab Insulation

• AC Unit Insulation (OEM/AHU/FCU/VAV)

• Water Pipe Insulation

• Tank Insulations.

• Raised Floor Insulation

• Underslab Insulation

• AC Unit Insulation (OEM/AHU/FCU/VAV)

• Water Pipe Insulation

• Tank Insulations.

Sizes

• Thickness: 3 mm to 50 mm (5mm, 10mm, 12mm,

25mm, 50mm Standard)

• Width: 1 m to 1.7m wide (1.0m, 1.2m Standard)

• Lengths: 2m to 50m length (to suit application / thickness dependant)

• Width: 1 m to 1.7m wide (1.0m, 1.2m Standard)

• Lengths: 2m to 50m length (to suit application / thickness dependant)

Thermobreak™ Thermal Insulation and

Thermobreak™ Tube applications include:

Thermobreak™ Thermal Insulation:

Thermobreak™ Tube:

• Tube Wall: 10mm to 50mm

• Tube ID: 10mm to 219mm, (avail for all common sizes of Copper, Steel & Plastic pipe)

• Length: 2m standard

• Tube ID: 10mm to 219mm, (avail for all common sizes of Copper, Steel & Plastic pipe)

• Length: 2m standard